Case Study: Lean & Continuous Improvement

Electronics Manufacturer Increases Capacity by 25% Through SMED And Focused Investment

Case Study: Continuous Improvement

Electronics Manufacturer Increases Capacity by 25% Through SMEDAnd Focused Investment

Helping clients

Achieve more by thinking lean

Case Study

This NZ based electronics manufacturer needed increase and sustain manufacturing capacity to meet their on going increasing order and customer based requirements.

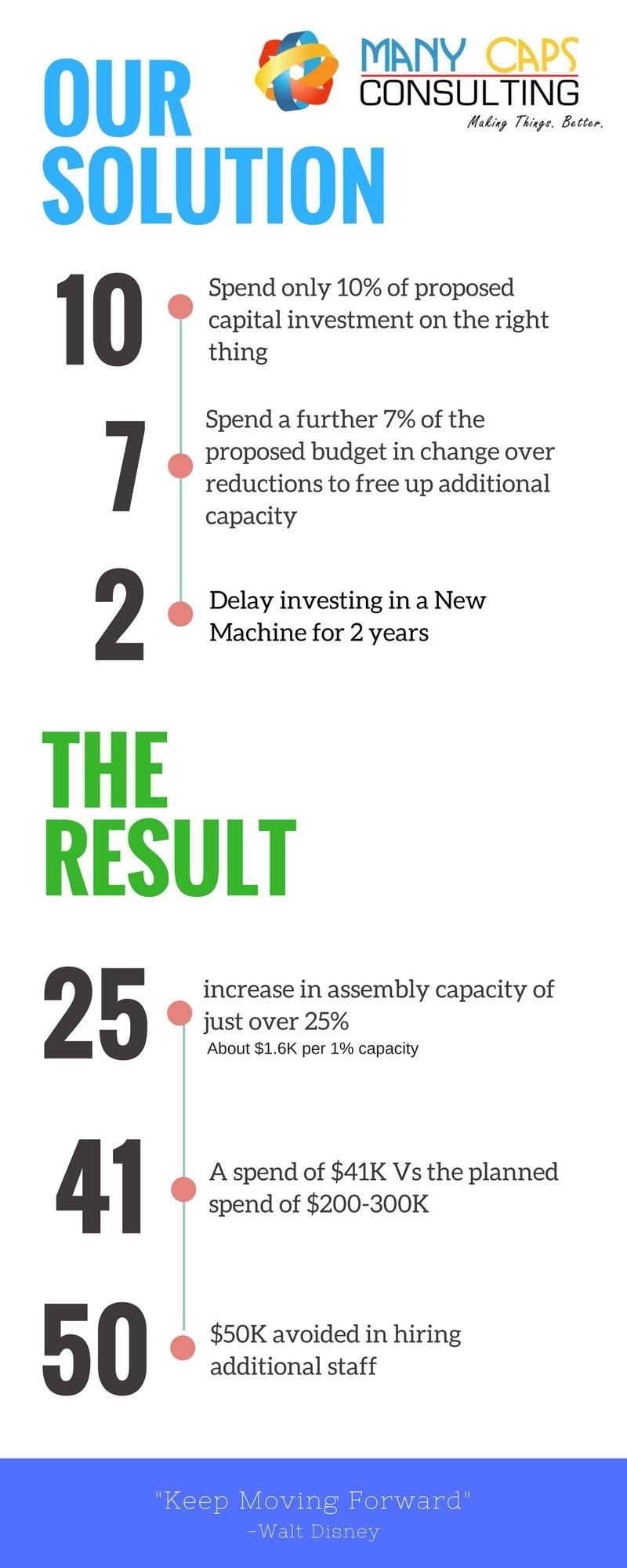

We were asked to help evaluate the capital investment options of a new machine to provide the increase in capacity with a budget of approx. $200-300K available.

How we helped

- High mix / low volume runs would drive a focus on fast changeovers rather than machine speed,

- High volume / low mix runs would drive a focus on machine speed with some sacrifice in change over times

- The current set up was built around total flexibility and the machines were in a standalone configuration having to be manually loaded & unloaded which increased downtime but was perceived to be more flexible.

- A desire to minimise training times and learning curves for new machines

We recommended that if the company did want to buy a new machine, they then should invest in the latest generation of what they had to reduce training time and allow reuse of existing equipment, this would give them 40% increase in capacity. However, this was our least preferred option.

As we reviewed the process through a series of observations, timings, data analysis and interviews with the team what we found was that the current processes were very wasteful.

The amount of time the machine was placing parts was only a small fraction of the real available time. A lot of the time the machine was idle waiting on new SMT boards to be manually loaded or unloaded, waiting on more parts to be added or in set up mode. All boards were being fully inspected prior to the main oven used to solder the boards because of a lot of manual placement and parts moving during transit between stations.

Furthermore, the amount of time lost in change overs was dramatic linked to work being done on line that could easily be done offline in a prep process.

All of this resulted in a lot of unused capacity that if we made the rights steps could become available for a lot less than the company felt they would need to spend, in many cases there was no cost at all other than time to implement and train the new process.

The answer to this challenge was to implement some basic lean thinking and SMED operations.

The Outcome

Achieving the right Results

Outcome

We worked with the team to focus on being ready for the change, that meant monitoring the output of the line in term sof quality and boards produced per hour and to know the target time for the runs. It also meant that we would introduce a daily stand up where we would review the runs for the next 2 days and hourly run boards to track performance.

This allowed us to ensure all the parts were available in advance for the next produciton run and we knew the right order to build in.

This then would result in:

-

A consistent & repeatable faster loading process

-

Additional capacity from the reduction in loading times - an average of 60 seconds down to 14 seconds per panel of boards

- A reduction in machine set up times creating free capacity

-

Improved through put of the line

-

Less rework from handling issues

If this new capacity generated the same revenue per hour as the company currently achieved this would equate to be between $750,000 - $1 Million in additional sales for the company.

Key to all of this was that we also gave the team the tools to understand the benefits of some basic lean thinking to improve thier business.